Over the past decades, the use of focus ion beam (FIB) techniques has become widespread for preparing specimens for microscopic investigations, including thin lamellae for TEM and needle-shaped specimens for atom probe tomography (APT). FIB allows to target specific features such as grain boundaries and interfaces with a spatial resolution of better than 100 nm and prepare a specimen suitable for microscopy and microanalysis by these other techniques. However, it is know that FIB milling introduces a range of structural defects because of beam-induced damage. This can lead to an amorphous surface layer, the creation of vacancies and self-interstitials, as well as possible extended defects, in particular disclocation loops, as well as the change of the composition of the material because of the introduction of ions from the FIB, usually Ga or, more recently, Xe.

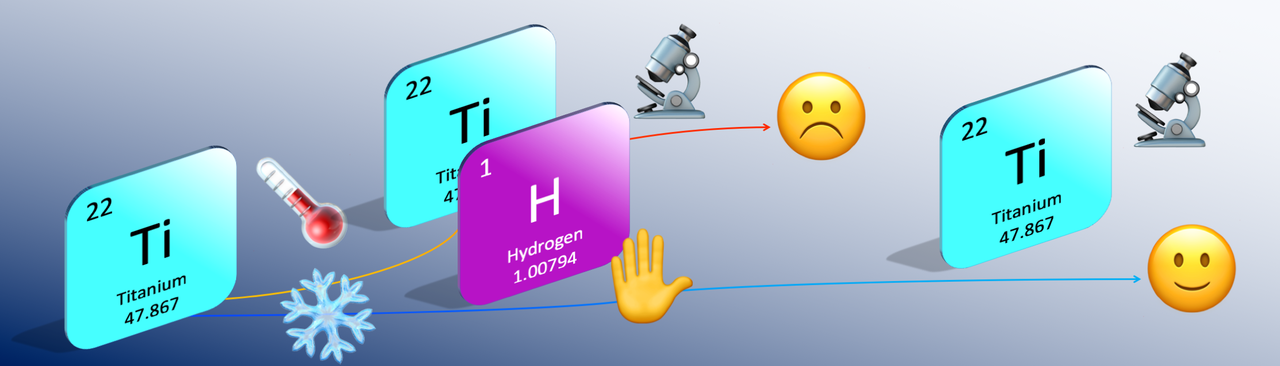

However, what we show in our new article published in Nature Communications, we demonstrate how to prevent FIB-associated introduction of spurious hydrogen within the structure of pure titanium and an engineering Ti-alloy. There had been reports of hydride formation in TEM lamellae and APT needles prepared by FIB, and of significant introduction of H within the microstructure of these materials (see Ding et al., Chang et al., Yan et al.). By maintaining the sample that is being milled at temperatures below -130C by a Xe-ion beam, we managed to prevent the accumulation of H within the specimen. We attributed this to the slowing down of the hydrogen inward diffusion, which remains close to the surface, in the region of the material's microstructure that will next be milled away.

Our findings are important because Ti is far from the only material that is likely to suffer from similar problems, yet the deep understanding of processes affecting the lifetime of Ti-alloys in service in demanding applications requires detailed high-resolution microscopy and microanalysis, for which specimens are often prepared by FIB-techniques. Since we wrote this paper, we also observed that the same results could be obtained with a Ga-beam and did not require the use of a Xe-plasma FIB.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in